How Is Moissanite Made?

How Is Moissanite Made?

Moissanite, a gemstone renowned for its brilliance, durability, and affordability, has emerged as a popular alternative to traditional diamonds in jewelry. But what exactly goes into the creation of moissanite? Understanding the comprehensive process behind its production provides insights into its unique properties and appeal.

Origins of Moissanite:

Moissanite was first discovered in 1893 by French chemist Henri Moissan, who found it in a meteorite crater in Arizona. Initially mistaken for diamonds due to its remarkable brilliance, it was later identified as silicon carbide (SiC), now known as moissanite. Natural moissanite is exceptionally rare and primarily found in meteorites and specific geological formations, making it a prized and sought-after mineral.

Synthesis of Moissanite:

The synthesis of moissanite involves replicating its natural formation process in a laboratory setting. There are several main methods used to synthesize moissanite:

CVD (Chemical Vapor Deposition):

In the CVD process, moissanite is created by depositing silicon and carbon molecules onto a substrate in a vacuum chamber. High temperatures facilitate the reaction between gases, typically methane and hydrogen, to form silicon carbide. The resulting moissanite is deposited onto a substrate, such as a silicon wafer, and carefully grown under controlled conditions.

PVT (Physical Vapor Transport):

The PVT process entails sublimating silicon carbide in a vacuum and depositing it onto a seed crystal. Silicon carbide powder is heated in a graphite crucible, causing it to sublime, and the vaporized silicon carbide travels to a cooler region of the crucible where it crystallizes onto a seed crystal. This method allows for the growth of large moissanite crystals with high purity.

Flux Growth:

Flux growth involves dissolving silicon carbide in a flux and allowing it to crystallize onto a seed crystal. A mixture of silicon carbide powder and flux, such as lithium and potassium fluoride, is heated to high temperatures and slowly cooled, resulting in the crystallization of moissanite onto a seed crystal. This method produces high-quality moissanite gems with controlled crystal growth.

Transformation into Gemstones:

Once moissanite crystals are synthesized using one of the above methods, they undergo a series of steps to transform them into gemstones suitable for jewelry:

Seeding:

A small moissanite crystal, known as a seed crystal, is placed in a growth chamber where it acts as a template for the growth of larger moissanite crystals. The growth chamber is filled with a mixture of gases and heated to high temperatures, allowing moissanite crystals to form layer by layer on the seed crystal.

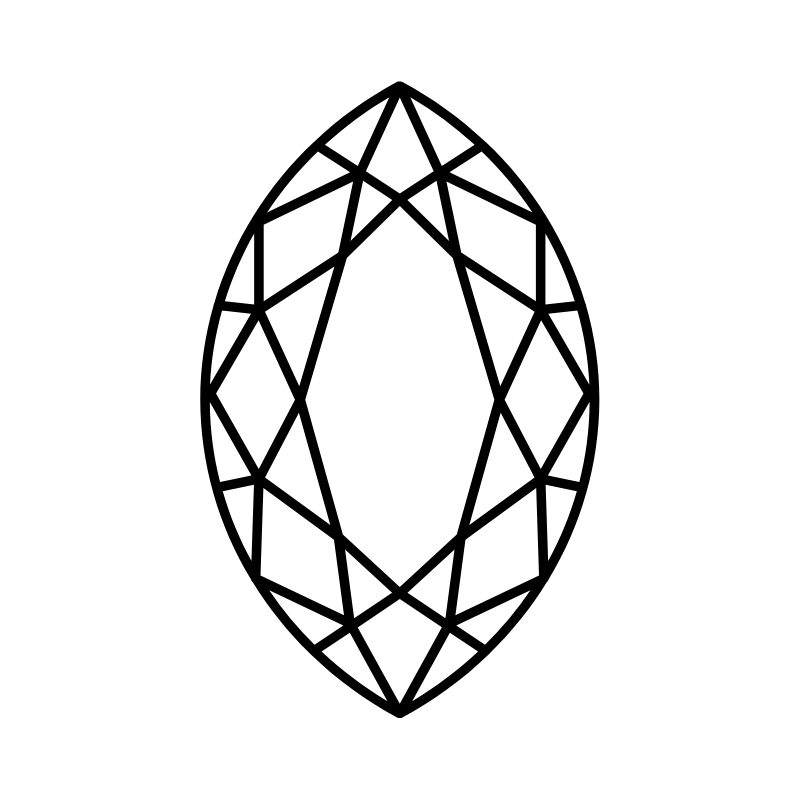

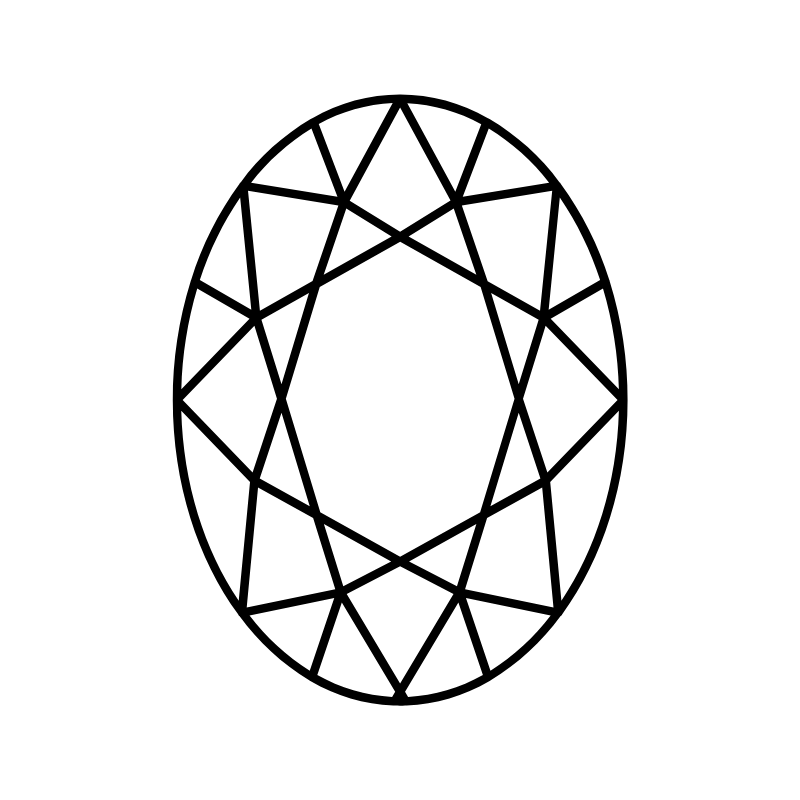

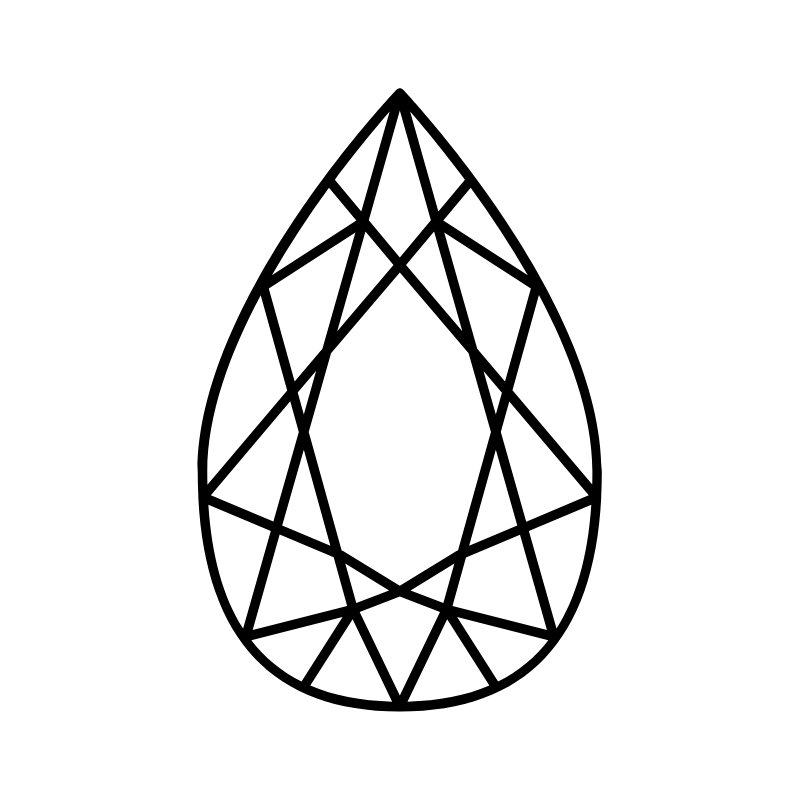

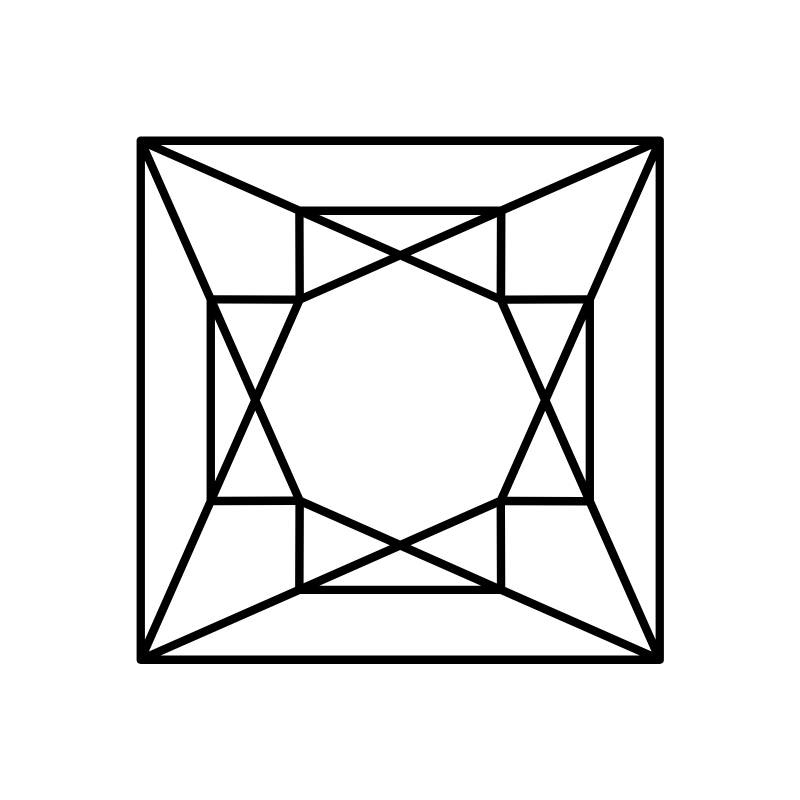

Cutting and Shaping:

After the moissanite crystals reach the desired size, they are removed from the growth chamber and inspected for quality. Skilled artisans then use specialized tools and techniques to cut the crystals into various shapes, such as round brilliant, princess, or cushion cuts. Precision cutting maximizes the gem's brilliance and fire, enhancing its visual appeal.

Faceting and Polishing:

Once cut, the moissanite crystals undergo faceting, where multiple flat surfaces, or facets, are created on the gemstone to reflect and refract light effectively. Faceting is followed by polishing to achieve a smooth and lustrous finish, enhancing the overall attractiveness of the gemstones.

Quality Control and Certification:

Throughout the manufacturing process, moissanite gems undergo rigorous quality control measures to ensure they meet stringent standards of clarity, color, and cut. Reputable manufacturers provide certifications guaranteeing the authenticity and quality of their moissanite products, offering consumers confidence and peace of mind.

Comparative Analysis with Diamonds:

Moissanite is often compared to diamonds due to their similar appearance and durability. However, there are notable differences between the two gemstones. While diamonds are formed through natural geological processes deep within the Earth's mantle, moissanite is created in a controlled laboratory environment. Additionally, moissanite exhibits a higher refractive index and greater fire than diamonds, resulting in exceptional brilliance and sparkle.

Environmental and Ethical Considerations:

One of the significant advantages of moissanite over diamonds is its ethical and environmental sustainability. Unlike diamonds, which are often mined under environmentally destructive conditions and may be associated with unethical practices, moissanite is produced in a controlled laboratory setting without the need for mining. This makes moissanite a socially responsible choice for environmentally conscious consumers.

The creation of moissanite involves a comprehensive and sophisticated process that combines scientific innovation with artisanal craftsmanship. From the synthesis of silicon carbide to the cutting, shaping, and polishing of the gemstones, each step is undertaken with precision and expertise. With its exceptional beauty, durability, and ethical sourcing, moissanite emerges as a compelling choice for those seeking a stunning and responsible alternative to traditional diamonds. Embracing the allure of moissanite allows individuals to indulge in timeless elegance while making a conscious and stylish choice.

Share